資材価格の高騰対策

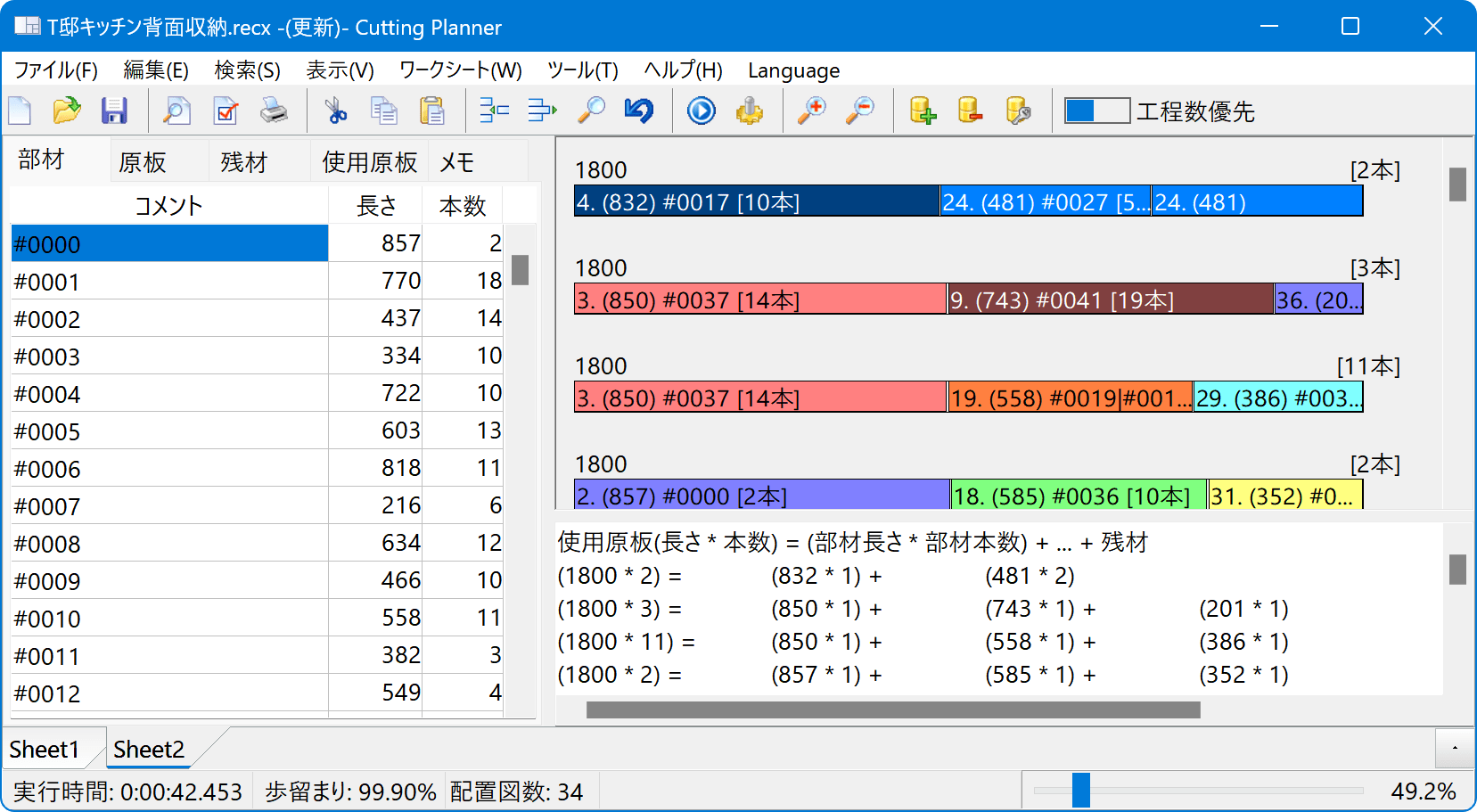

板材の木取り/板取計算

鋼材カット計算アプリ

30日間無料

- 鋼材・バー・パイプ・など長尺材 (1次元)

- 合板・ベニヤ・鋼板・アクリル板・などの板材(2次元)

両タイプの材料取り計算に対応、資材と人件費を節約します

Windows 11に対応 (仮想環境での試用は不可)

2026/02/12 Version 15.18: 更新履歴

見積もりを簡単に、時間も節約

資材の切断計画を立てるとき、パズルみたいで困っていませんか?

高歩留まりなカットレイアウト図を計算します

材料取りソフト / 板取・木取りソフト - Cutting Plannerとは

CuttingPlannerは、家具製造、鋼板・板金加工、その他幅広い分野で利用されます。

材料と部材のサイズを入力するだけで、切断計画を提案します。

板材(2次元)はパネルソー・ランニングソー・シャーリングなどを用いたパネルを一直線に切断するタイプの資材割り付けを行います。

計算結果はPC画面上で木取り図を確認することができ、印刷することで指図書として利用可能です。Cutting Plannerを使えば、熟練の職人に頼る必要はありません。割付を考える時間をなくし、すぐに作業が始められます。資材・廃棄物・エネルギー・管理コスト、そして時間を節約します。

使い方は簡単

迅速な見積もり、無駄のない資材発注、職人に頼らない切断指示書を実現

切断計画を作成するには熟練の経験と勘、そして相当な時間が必要です。板取ソフトを使えば職人は必要ありません。割付を考える時間をなくし、すぐに作業が始められます。

マルチコアプロセッサ対応でPCの能力を最大限に活かします。

節約できるのは資材と時間だけではありません。相乗的にコスト削減効果があります。

無形資産への投資をしてみませんか。

- コマンドラインオプションを利用した自動計算・自動入出力。在庫管理システムと連携させている事例があります

- 独自のデータ形式にxml形式を採用。その仕様を公開。出力させた切断レイアウト図を活用するソフトウェアを独自に開発可能です

- CSV形式での入出力

- Excelなどのスプレッドシートとのコピー・アンド・ペースト

- 計算可能な原板と部材の種類と枚数は実質無制限(メモリに依存)

- 複数サイズの原板を設定すると自動で効率が良いように部材を割り振ります

- 部材の回転の可否の個別設定

- アサリ寸法・カットマシンの最大切断長を考慮した配置

- どこから切り出したら良いのかわかりやすい切断補助線

- 直感的に操作できるユーザーインターフェース

- ご購入後はオフラインでの動作が可能

- 一度購入すればず~っと使える無期限ライセンス

- バージョンアップ無料で維持費ゼロ。早く初めて長く使うほどにお得、利益を生み続けます。

- 10台のPCにインストール可能。(同一組織内または個人であること)

単純にできる限り板材を詰め込むだけの探索はしていません

同じ歩留まり(原板使用枚数)の範囲内で作業工程数を減少させる図の出力をします

- 1次元: 工程数(図数)優先と残材長さを優先した配置を選択可

- 2次元: 1次元と同様の複数候補列挙機能

導入事例・お客様の声

メールなどで実際に届いたお客様の声を抜粋して紹介いたします。実際にはエラーが出た・不具合があるなど教えていただけることも多く、そのたびに改善することでより信頼性を高めています。

- 原板からの材料採りも使い勝手が良く助かっております。

- 購入もしていないのに、ご丁寧に対応頂きました。

- 大変有用なソフトで、ありがたく使わせてもらっております。

- 計算スピードや計算結果に満足しています。

- 活用すれば、板の歩留まりアップは確実です。

- このソフトは大変すばらしく、使い勝手も良く部署内で検討後、利用させて頂くことになりました。

- SUS薄板の切り出しに使用させていただいています。

- 手作業でやっていたものが短時間で済むようになりました!

- コストパフォーマンス最高です。

- コマンドラインオプションで在庫データと連携しています。

- 数時間かかっていた作業が数秒で終わり感銘を受けました。

実際の工場作業よって得た経験とコンピュータの長所を融合させた独自のソフトウェアを開発しました。

超高速かつ高歩留まりをまずは無料で体験してください。